Primary Cementing Job

The main objective of primary cementing is placing cement slurry behind the casing. This can be performed in different methods: single stage, multi-stage and inner string cementing. In single stage, the cement is pumped into the casing, down to the shoe then up into the annulus. In some cases, when the casing string is long or the formation cannot support the hydrostatic pressure of a column of cement, a multi-stage can be applied. The procedure is cementing one part of the annulus, and then the second part is cemented by pumping the cement through a multi stage tool from the casing to the annulus up to the surface or pre-determined depth.

The height of the cement in the annulus depends on the objective of the job. For the conductor and surface casing, the annulus is covered all the way to the surface in order to provide more support to the casing. For the intermediate and production casing, the top of cement depends on the troublesome zones which have to be covered.

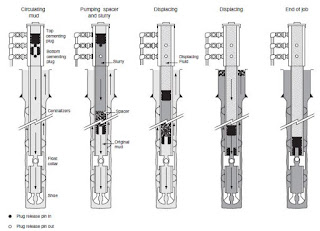

Single Stage Cementing Job:

It is the most common cementing operation in the drilling process. After running the casing with all its accessories: shoe, float collar and centralizers, and spacing out the casing string from the bottom, the cementing head is set at the top of the string. It has to be sure about the top and bottom plugs which are very important for a successful job. The casing is circulated at least for one string volume to clean it and to cool the bottom of the wellbore. The spacer is pumped and then the bottom plug (wiper plug) is dropped. The cement is pumped after dropping the bottom plug, and then the cement is followed by the top plug. When the bottom plug reaches its seat at the float collar, its diaphragm is ruptured (Pressure increase at the surface is an indication of plug landing) and the cement flows through the plug down to the casing shoe, up into the annulus. When the top plug reaches the float collar, it lands on the bottom plug and stops the displacement of the cement by the drilling fluid. The pumping rates should be slowed when the plugs reaches the float collar. The casing has to be pressure tested when the top plug lands on the float collar. The pressure has to be bled off slowly to check the valves functioning in the float collar and the casing shoe. If there is any back flow, the volume has to be pumped again, increase the pressure and keep it till the cement hardens.

|

| Fig 01- Single Stage Cementing Job |

The displacement volume has to be well estimated before the job and controlled during the operations. When the volume is nearly to be totally pumped, the flow rate should be slowed to do not generate any excessive pressure when the plugs lands on the float collar. The mud return should be closely monitored to check if there is any fluid losses while cement displacement.

|

| Fig 02- Cementing Head |

Multi-Stage Cementing Job

This procedure of cementing is used when the pumping rate is long, high pump pressures or the hydrostatic pressure can exceed the fracture pressure of some troublesome formations. The operation is split into two stages:

- First stage: this part of the job is similar to single stage cementing except that a bottom plug is not used. A special plug is used to pass freely through the stage collar. the first stage is performed after the cement plug lands at the landing collar

- Second stage: this final part of the job requires the use of a stage collar which allows pumping cement from inner part of the casing string into the annulus. The openings in the stage collar are sealed off by the inner sleeve. When the first stage is completed, a special dart is dropped from the surface and lands in the inner sleeve, and then the pressure is increased above the dart to open the ports. The annulus is cemented by pumping slurry through the ports, then a cement plug is dropped and displaced by drilling fluids till it lands at the stage collar, then the casing string is pressure tested.

|

| Fig 03- Mutli-Stage Cementing Job |

Inner String Cementing

- Large displacement volumes

- Long pumping time

- Plugs can stuck in the casing due their large dimensions

Inner string cementing is performed by using the stinger which is run by the drill pipe to the casing shoe and stubbed in it. Once the stringer is engaged, drilling fluids are circulated to ensure that there is no leak which can allow fluids to flow from the drill pipe into the casing. The cement slurry is then pumped through the drill pipe, down to the casing shoe up to surface through the annulus. The job is finished when getting cement on surface into the cellar and then the stinger is disconnected and pulled above the shoe. Circulation through the drill pipe is necessary in such situation to flush the drill pipe from any cement. In this type of cementing operations, no cement plugs are used.

|

| Fig 04- Inner String Cementing Job |

Squeeze Cementing Jobs

This type of jobs is based on forcing the cement slurry through perforated casing into the annulus or the formation. Squeezing process is performed as a remedial operation and it is applied to:

- Maximizing oil production by sealing off gas and water production zones.

- Cementing parts of the annulus in case of primary cementing failure

- Sealing off lost circulation

- Preventing undesirable fluids migration into producing zones

- Repairing casing by forcing cement at leaking points

The squeezing jobs are performed in two ways: high pressure squeeze and low pressure squeeze.

High pressure squeeze

In this process, the formation is fractured in order to allow slurry to flow into the fractured zones. The formation is initially fractured by pumping solids free fluids like water or brine to avoid making a filter cake. The fractures appears in the perpendicular plane to the less compressive stress. After fracturing the formation, the slurry is placed against the fractured zones and forced with slow rate to flow into fractures. When the cement is squeezed, any back flow is checked by releasing the pressure.

Low pressure squeeze

In this process the fracture gradient is not exceeded but the cement slurry is spotted against the formation, and when increasing the pressure, the fluid content of the slurry is forced to flow into the formation and the solid materiel of the cement builds a cake on the outer part of the formation. Applying this process helps to create an impermeable barrier across the perforated zone. Designing and controlling the fluid loss additives is very important in such operations. High fluid loss results in rapid dehydration of cement which leads to bridging and this can make it difficult to seal off the other perforated zones. Very low fluid loss leads to long process time due to slow filter cake building up.

Low pressure squeeze can be carried into two processes:

- Running squeeze: the cement in this process is pumped slowly and continuously till reaching the final planned pressure.

- Hesitation squeeze: in this method the slurry is allowed to dehydrate and form a required filter cake by stopping the pumping at planned and regular intervals of time.

Cement Plugs

Cement plugs are placed into the casing or the open hole for many purposes:

- Abandoning depleted zones

- Sealing off lost circulation zones

- Sidetracking or directional drilling

- Abandoning the entire well

There are two techniques to place cement plugs: dump bailer and balanced plug.

Dump bailer: this method requires the use of a bridge plug. The tool which contains the cement slurry is run with the wireline and it is opened when it touches the bridge plug and then the cement is dumped while pulling the tool. This method is used for shallow depths.

Balanced plugs: it is the most common method. It is performed by running drill pipe string or tubing at the desired depth. The mud contamination is avoided by pumping spacer to provide proper placement. The volumes should be carefully calculated to obtain equal height of cement in the annulus and the drill pipe string when completing the displacement and then the string is slowly pulled with no rotation in order to do not disturb the balanced cement plug.

Appreciate the recommendation. Will try it out.

ReplyDeleteIt's enormouss that you are getting ideas from this article as well as

ReplyDeletefrom our dialogue made here.

Really happy to receive your feedback, thank you for all of you

ReplyDeleteChoosing the right career is one of the most significant decisions in your entire life. You should carefully consider all the details and choose something that makes you happy or at least satisfied.

ReplyDeletejob career changing

Thanks for sharing this interesting information.

ReplyDeletebank job circular

Thanks for sharing your thoughts. I truly appreciate your efforts and

ReplyDeleteI am waiting for your further post thanks once again.

Hi there, I enjoy reading through your post. I wanted to write a little comment to support you.

ReplyDeleteVery nice article, totally what I wanted to find.

ReplyDeleteNice post... Thanks for shearing

ReplyDeleteAll Bank Jobs Circular in Bangladesh

Very nice article.Thanks for sharing

ReplyDeleteSaved as a favorite, I love your web site!

ReplyDeleteThanks for viewing up such useful information. I like this post, keep writing and give the useful post like that.

ReplyDeleteYou have noted very interesting details! ps nice website.

ReplyDeleteI love the efforts you have put in this, appreciate

ReplyDeleteit for all the great blog posts.

Great article, just what I wanted to find.

ReplyDeleteLike!! Great article post. Really thank you! Really Cool.

ReplyDeleteHere you will learn what is important, it gives you a link to an interesting web page: Employment Agency New York

ReplyDeleteMachine Learning Projects for Final Year machine learning projects for final year

ReplyDeleteDeep Learning Projects assist final year students with improving your applied Deep Learning skills rapidly while allowing you to investigate an intriguing point. Furthermore, you can include Deep Learning projects for final year into your portfolio, making it simpler to get a vocation, discover cool profession openings, and Deep Learning Projects for Final Year even arrange a more significant compensation.

Python Training in Chennai Project Centers in Chennai